Core Filling Food Processing line

Description:

Core filling snack/Puffed leisure food production line can do the works of raw materials preparation, ectrusion, core filling, shaping, cutting, coating and flavoring at a time, which is high automation degree. It has the advantages of more machines choice, flecible and diverse configurations, wide range of raw materials application, numerous in products variety and easy operation. It can make the puffed food, such as core filling snack food, filling biscuit, nutrition breakfast, corn flake etc. After being puffed, the products are crispy, easy to digest and unique taste. They are the perfect leisure food for consumers.Advantage

- 1. Capacity: 100kg/h -800kg/h and work flow can be customized.

- 2. Products: Core filling snack food, filling biscuit, nutrition breakfast, corn flakes, etc.

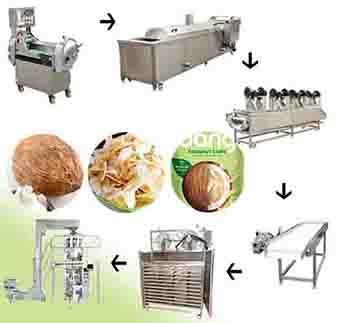

- 3.Details of core filling snack making machine Mixer--- Screw Conveyor --- Double Screw Extruder --- Core Filler --- Multi-function Shaper --- Large Hoister --- Dryer --- Double Roller Favor Machine --- Packaging Machine

- Description

- Advantage

- Parameters

- Application

- Video

Core filler snack food making machine includes batch mixer and screw feeder, twin screw extruder and forming equipment, filling stuff equipment, Belt dryers and coating drum. This process line adopts advanced extruding technique which can extrude snacks with different texturesand tastes out of double-screw extruder.

Details of core filling snack making machine

Mixer--- Screw Conveyor --- Double Screw Extruder --- Core Filler --- Multi-function Shaper --- Large Hoister --- Dryer --- Double Roller Favor Machine --- Packaging Machine

Core Filling Food Processing line Product Description

Core filler snack food making machine includes batch mixer and screw feeder, twin screw extruder and forming equipment, filling stuff equipment, Belt dryers and coating drum. This process line adopts advanced extruding technique which can extrude snacks with different texturesand tastes out of double-screw extruder.

By changing moulds and assistant equipments, it can also produce nutritional powder, grain gruel and many other leisure snacks in different shapes.

This automatic process line is of leading level for its superior characters, such as,applied to many materials, convenient operation and maintenance, low power consumption, high output.

Adopts corn, rice, wheat, oat, barley etc as ingredients.

3. Products:

Variety shapes are available for the core-filled food, including pillows, tubes, bars, long and short ovals, heart shape by adjusting the roller in the shaper. Also can produce snacks cereals by adjusting the mould from extruder.

4.Core Filling Food Processing line Capacity: 100-500kg/h

5.Core Filling Food Processing line Flow Chart:

Mixing system----Extrusion system----Core filling and shaping system----Drying system---- Flavoring system----Packing system

6. Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers'local voltage according to different countries.

7.Machines Materials:

All the machines are made by stainless steel

8.Detailed information of Core Filling Food Processing line

a. Twin screw extruder----DT-90 with capacity of 100-500kg/h

b. Core filling machine

Core-filler machine is used for co-extruding with extruder. There is an electrical heating pipe to melt stuffing.There is an interlayer in the mixing tank, the water is put into the interlayer.

c. Different shaper for core filled snacks

Features of core filling process production line for sale:

* 1. Corn flour puffing snack machine has complete design and advanced technology.

* 2. Easy to operate, stable and efficient

* 3. Corn flour puffing equipment can be customized according to different requirements of customers.

* 4. Long service life, easy maintenance

Core filled puffed snack food making machine parameters

|

Name |

Solution |

Output(kg/h) |

Power(kw) |

Size(mm) |

|

Snack food |

Mixer-Screw Conveyor -Double Screw Extruder -air conveyer-Dryer -Double Roller Favor Machine -Packaging Machine |

100-120 |

Gas: 45 Electricity: 108 |

15000*800*1600 |

|

Jam center food |

Mixer -Screw Conveyor -Double Screw Extruder -Core Filler -Multi-function Shaper -Large Hoister -Dryer -Double Roller Favor Machine -Packaging Machine |

100-120 |

Gas: 45 Electricity: 113 |

18000*800*1600 |

Application

1.Variety shapes are available for the core-filled food, including pillows, tubes, bars, long and short ovals, heart shape by adjusting the roller in the shaper.

2.Also can produce snacks cereals ect by adjusting the mould from extruder.

Video of core filled puffed snack food processing machine

More info

Thank you for visiting our website! We endeavors to produce food machinery, potato chips, banana chips, chicken process, etc. If you have any question, please feel free to submit this form with any questions or comments. We will answer your message within 24 hours.We regularly attend kinds of exhibition, which let more customers understand our products, quality and service. Through these exhibition, we established long-term cooperation with many customers from Europe, Asia, South America and many other regions and countries. Customer feedback: